Sentinel Bay Bridge

Marine-grade concrete, high-tensile cable logistics, 24-month program.

- Precast segment delivery windows

- Anti-corrosion rebar supply

- Nighttime barge offloading

- On-site QC & batch tickets

A selection of recent, large-scale deliveries—bridges, healthcare, transit, aviation, and high-rise.

Marine-grade concrete, high-tensile cable logistics, 24-month program.

MEP component staging, isolation slabs, chain-of-custody tracking.

Composite decks, high-strength steel, night-shift lifts.

Multi-modal station core with platform canopies, escalator wells, and below-grade concourse works.

Airside logistics for long-span roofs, curtainwall systems, and baggage-handling integration.

Tiered seating rebuild, bowl steel, precast stairs, and distributed MEP risers on game-day schedule.

Quay reinforcement, RTG crane rails, and corrosive-environment materials with barge-side supply.

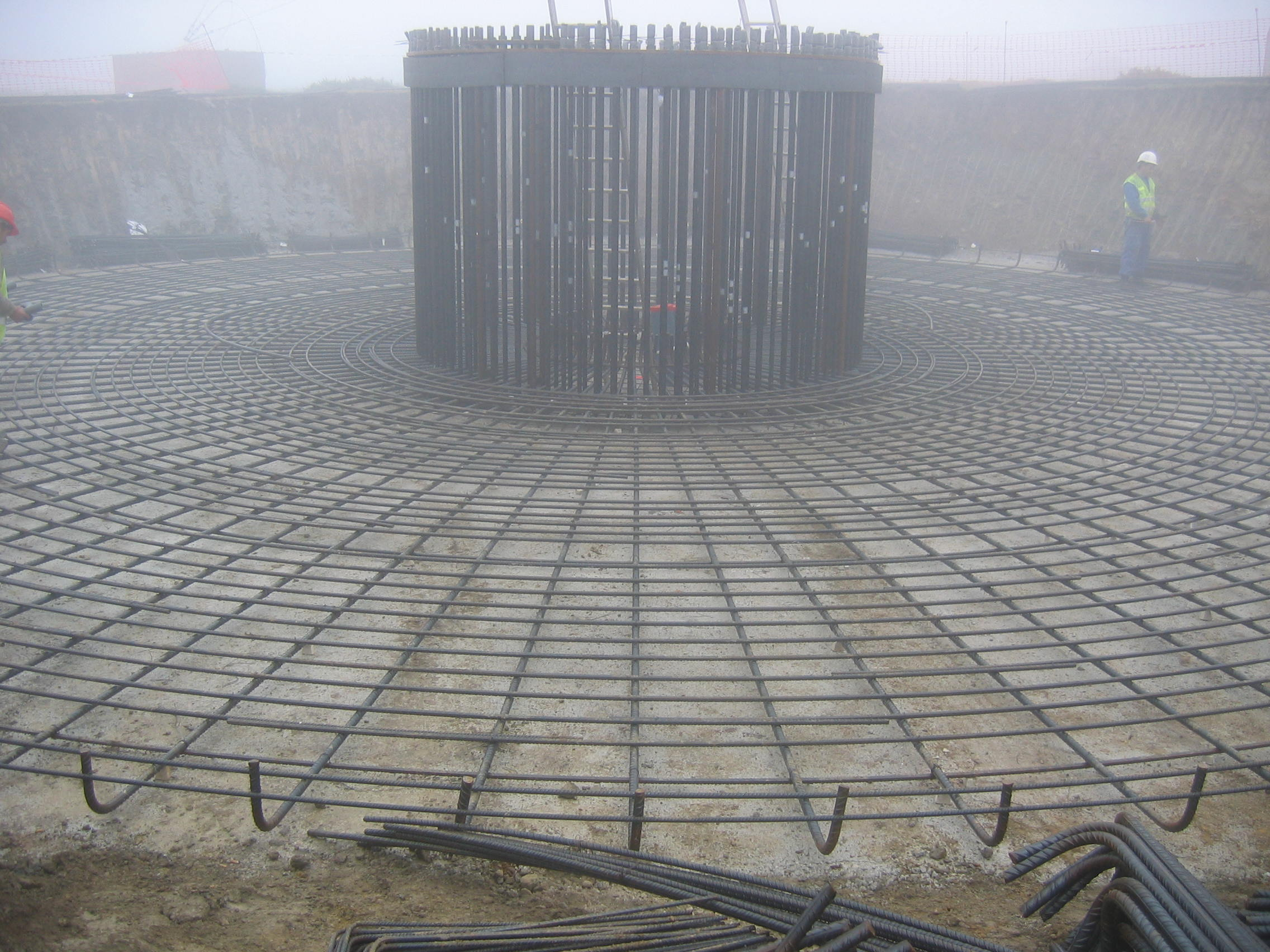

Foundation cages, access roads, and nacelle lift coordination across remote ridge lines.

Pile-driven racking, combiner boxes, and DC cabling across multi-hundred MW arrays.

Mass concrete placement, penstock steel, and spillway formwork with continuous QC testing.

Kilometer-scale conveyor trestles, dust-control enclosures, and abrasion-rated chutes.

Cut-and-cover tunnels, TBM segment supply, and station fit-out with staged handovers.

Pre-treatment basins, RO hall steel, chemical storage, and corrosion-resistant piping.

Lab-ready shell & core with vibration criteria floors and clean-service utilities.

High-bay frames, process trenching, and mezzanine systems for final assembly lines.

Fast-track shell, hot/cold aisle containment, and critical power backbone.

Flyovers, retaining walls, and MSE systems delivered with live-traffic coordination.

Historic masonry strengthening with fiber wraps, anchors, and discreet steel frames.

Multi-tower podium with shared parking decks, amenity slabs, and façade logistics.